电话:18925320648

Welcome to Zhongshan Sktfilter Clean&Purification Co.Ltd. official website!

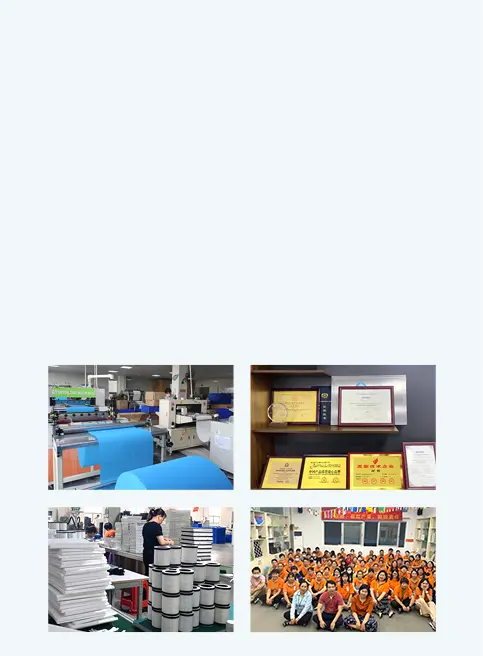

“ 源头工厂 专业品质 ”

专注15年空气净化领域设计定制

协助1021家企业成功开发1772款产品成功上市

荣获46项专利和认证

电话:18925320648

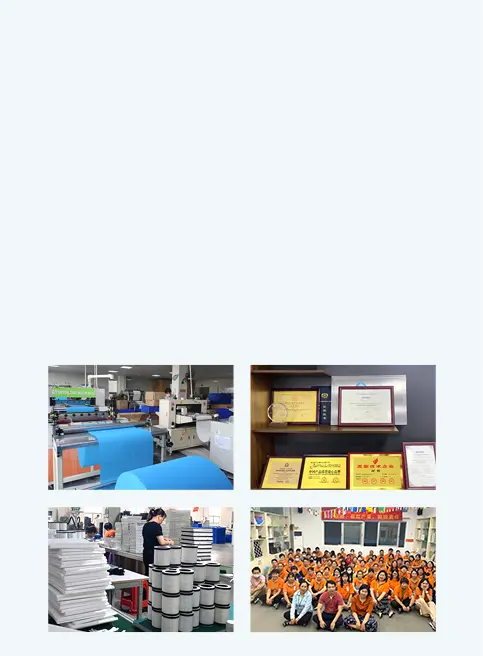

“ 源头工厂 专业品质 ”

专注15年空气净化领域设计定制

协助1021家企业成功开发1772款产品成功上市

荣获46项专利和认证